Container industry has constantly evolved with rapid development in the international supply chain. 8 types of reefer containers are commonly used in supply chain logistics that preserve the shelf life of perishables and other high value added commodities. To preserve the quality of perishable goods during transport, specific temperatures need to be set in the containers carrying the goods. Various types of reefer containers allow temperature control, humidity control. continuous monitoring of containers is done with data loggers, and micro processors. containers are also installed with modems, this advanced technology is adapted in most of reefer containers for remote monitoring through IOT applications.

1. Closed Reefer container

The closed reefer is the most common type of reefer. This type of reefer is made of one piece with an integral front wall. The integrated heating and cooling unit enable it to be used with all seagoing containers that conform to ISO standards.

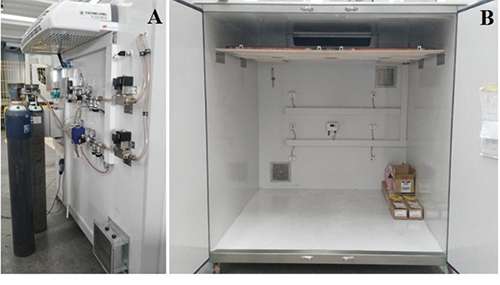

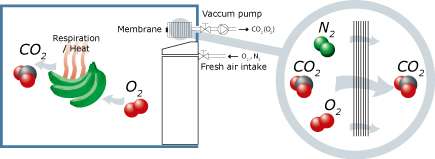

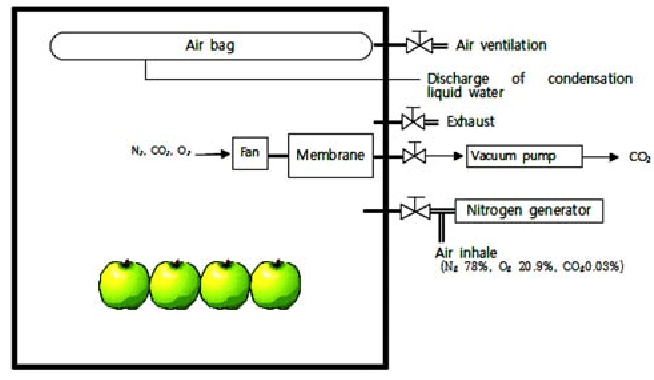

2. Modified/Controlled Atmosphere (MA/CA) type reefer container

The technology applies more often to preserve shelf life of avacado, blueberry, apples and bananas .It controls component ratio of nitrogen,oxygen,carbon dioxide,ethylene,and also humidity, temperature,and air pressure inside the container to slow down metabolism,and keep fruits under a dormancy condition.In this way,products’freshness can be properly retained.

MA/CA container units are distinguished from closed reefers by their enhanced insulation. In order to maintain a consistent interior environment, specialized air exchange controllers replace oxygen consumed, ensuring the environment matches cargo specifications throughout the journey.

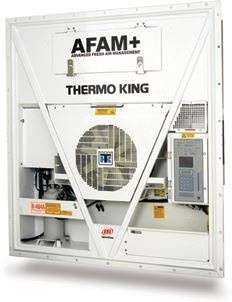

3. (AFAM)Automatic Fresh Air Management reefer Containers

AFAM containers are effectively an upgraded version of MA/CA containers and are the most sophisticated reefer containers available on the market today. By using an array of sensors to adjust the fresh air exchange rate, this type of container is able to precisely control oxygen and carbon dioxide levels, effectively extending the shelf life of the cargo inside.

AFAM+ has an enhanced capability to adjust the air vent positioning automatically in order to maintain the correct balance of carbon dioxide and prevent product dehydration.

Effective on a wide variety of fresh produce, including avocados from Kenyon, asparagus from Peru, bananas from Ecuador, and sweet corn from North America, Advanced Fresh Air Management technology has helped preserve post-harvest conditions in thousands of perishable loads of varying voyage lengths through the years.

4. Cryogenic Cooling Reefer Containers

Dry ice or liquid nitrogen is used for the cooling process in cryogenic reefer containers. Because it sublimes at -78.5°C, dry ice is a powerful refrigerant mainly used to transport frozen goods.The cryogenically frozen gas (liquified nitrogen) evaporates slowly, cools the container, and is then vented out into the atmosphere. On average, these containers can maintain their temperature range between 20 days to 30 days. Dry ice containers have grooves on the inside walls that serve to optimize the natural convection and allow the cold air coming from the sublimation of the dry ice to circulate around and through the load being transported.

The dry ice must be placed at the top of the insulated container, if possible above the load of frozen goods. Insulated containers can be fitted with a metal drawer (optional extra) containing the dry ice and diffusing the cold evenly through the container.

5. Dual Redundant type Reefer Containers

Maintans temperature from -8ºC to 25ºC with Dual Redundant Refrigeration Unit & Integral Genset

» Two full capacity reefer units offer total redundancy—each reefer has their own thermostat and control circuit

» Complies with international regulations for the transport of dangerous goods

» Integral genset powers reefer units are used, when shore power is not available

When transporting highly valuable, temperature-sensitive, or hazardous cargo; the system’s reliability is of utmost importance. Redundant Refrigeration Reefer Containers are used in such cases. These containers have a primary as well as a secondary backup refrigeration unit. Reefers can be customised with multiple refrigeration systems and run using a Genset or plugged into a source. This ensures that extreme temperature-sensitive products can be safely transported.

The automated operation of the system eliminates the need for manual intervention, which prevents a time lapse that could cause product spoilage. Diesel generators typically serve as a reliable power source for both units.

6. Blast Freezer container

Blast Freezers can freeze cargo up to -40C within 24 hours. This instant and quick freezing capability reduces the need for the cargo to be pre-frozen before loading. These containers are capable of Flash Freezing the cargo and thereby halting bacteria growth which aid in decomposition.

These containers come in 10ft, 20ft and 40ft sizes and usually have doors on both ends. While a 10ft Blast freezer can freeze 1000 Kgs of lean fish from +30C to -18C in around 5 to 6 hours, a 40ft Blast freezer can reach -18C in less than 2 hours. These containers can also help with tempering the cargo from -18C to +2C in less than 3 hours for one kilogram of meat. The main objective of the Blast Freeze technology is to bring the core temperature of the commodity to -18C.

7. Refrigerated or Cool Tanker Containers

Designed to transport products like pharmaceuticals, milk, and general-purpose liquids. These tanks are cooled by circulating brine or synthetic oil around the external coils

8. Super Freezers containers-Ultra-low temperature for critical cargo

Super freezers are the height of innovation freezing technology in the containers industry. These containers are capable of keeping goods stored up at a staggering -70C temperature. The recent pandemic brought the whole world to a stop and everybody turned towards their wait for vaccines. These vaccines needed to be stored at sub-zero temperatures to ensure they are kept intact and the composition and integrity of the vaccines are not compromised. Super freezers made it possible for vaccines to remain in good care before being transported via air, sea or land across the globe.

Super freezer can freeze up to -70C from ambient temperatures of -30C to +50C. Its exceptional high performance offers protection for valuable pharmaceuticals or blood plasma, and preserves first-day product freshness of seafood (Grade A sashimi, tuna, salmon). Giving the possibility of moving cargo to great lengths. These containers have a strong connection within the pharma industry, but it does not stop there. The fish and meat industry uses super freezers at great volumes to store frozen produce.

This is because a super freezer will help freeze the cargo and completely stop bacterial resultant decomposition. And is a solution that can be adopted at the very beginning of the cold chain.