An exporter, trading in export of fruits, vegetables, meat, sea food, medicines and beverages, always have the dilemma of how to export the perishable goods, which have a very short shelf life. Supply chain management internationally would not be possible without the introduction of reefer container. Reefer containers play a major role in the cold supply chain management. In particular, the supply chain for food products, medicines, and vaccines, pharmaceutical chemicals, are completely dependent on the availability and performance of a refrigerated (reefer) container.

what is a reefer container? what is it used for?

One of the most important container types in the market are reefer containers. Reefer containers are used to ship perishable goods. It can carry temperature sensitive goods at the required temperature, needed for transportation and storage of the product. There by increasing the shelf life of the goods and ensuring the quality of the product exported, is maintained. The reefer container has a built- in large refrigerator unit at one end.

Reefer’s ship perishable food items that require refrigeration. Some of the most commonly shipped food items are:

- Meat (frozen and chilled),

- Seafood

- Fruits and vegetables

- Milk and dairy products

- Processed food

- Juice and beverages

- Wine, etc.

what are the temperature ranges for transportation of perishable goods?

Depending on the type of product being transported through the cold chain, specific temperature standards are enforced. For products such as fruits and vegetables, improper temperature control measures, can lead to damage such as softening, bruising, unwanted ripening, color changes, texture degradation, and the development of rots and molds, all of which can degrade their value and marketability.

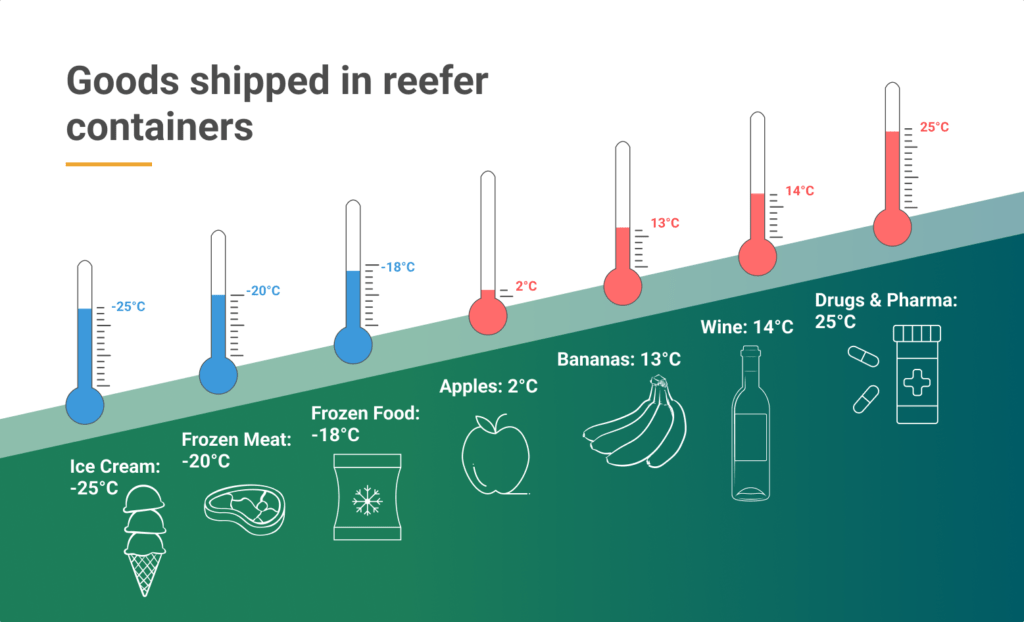

Although optimal transport temperature is product specific and that a wide variety of temperature setting can be selected, seven temperature standards are among, the most commonly used in reefer containers.

Reefer container temperature guide:

- Deep freeze (-25 to -30 Celsius) This temperature range is used for transporting seafood, shrimp-which is the world’s most consumed seafood and ice cream.

- Frozen (-10 to -20 Celsius). Used for transporting frozen meat, including beef, poultry, and pork. Frozen bakery (cakes, bread) also falls within this temperature range.

- Chill (2 to 4 Celsius). This range is used to transport fruit, vegetables, and fresh meat, as it confers optimal shelf life without freeze damage.

- Pharmaceutical (2 to 25 Celsius). This temperature range is used for transport of pharmaceutical goods, like vaccines. However, pharmaceuticals are rarely transported in ISO reefers, but in smaller refrigerated packages for van and air transport.

- Banana (12 to 14 Celsius). This temperature range is chosen for one of the world’s most-produced fruit that usually has its ripening controlled during shipping. It is also used for most tropical fruits (oranges and pineapples) and vegetables (tubers such as potatoes).

Temperature standards are easier to implement and monitor since they apply to a wide range of temperature-sensitive goods. Yet, reefers can also be adapted to maintain a specific temperature requirement of any given product.

How does a reefer container work?

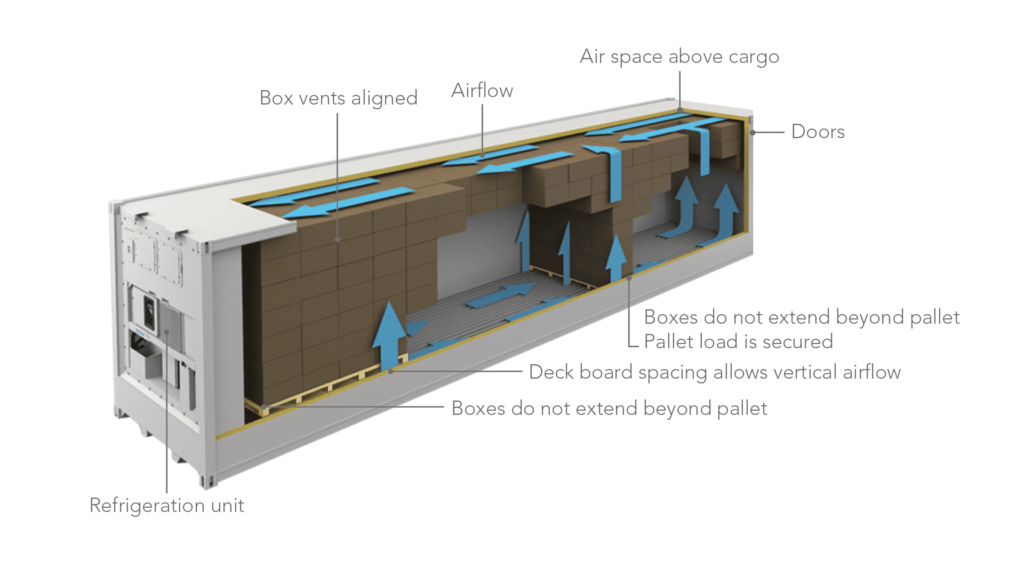

The reefer container has a built-in large refrigerator at one end, which maintains the temperature range between -30°C and +30°C. When connected to a power source, the unit fills the container with chilled air. The airflow maintains the desired temperature, making a reefer container perfect for storing food items, pharmaceuticals, plants, and other temperature-controlled goods.

The refrigeration unit distributes the chilled air through the floor of a reefer container. If you look closely, the floor of the container has grooves, also known as T-shaped decking. This T-shaped decking provides a constant supply of fresh air surrounding the shipment.

An important thing to note is a reefer cannot reduce the temperature of your goods. A reefer container only maintains the desired temperature. So, as an exporter, you have to pre-cool the cargo to the temperature you want the reefer to maintain.

Do you need a Genset equipped reefer container?

Genset is short for generator set. It provides electricity to the refrigeration unit to work. A reefer is usually connected to a power source on vessels. But for extremely sensitive cargo that could spoil outside a temperature range, gensets provide a backup power source. It’s best to use a genset equipped reefer to ensure the safety of your cargo

Temperature variation depending on the container type

| The temperature range varies as per the container type |

| 40′ High Cube Standard Reefer: -30C to +30C |

| 40′ High Cube Standard Reefer: -30C to +30C |

| 40′ High Cube Magnum Reefer: -35C to +30C |

| 40′ High Cube Star Care™: -30C to +30C |

| 40′ High Cube Super Freezer: 60C to -10C |

| 20′ Standard Reefer: -30C to +30C |

Advantages of using a reefer container:

- proper Ventilation keeps goods fresh.

The entire point of a reefer container is to keep your goods fresh. Fruits and vegetables release heat, water, and CO₂. If these gasses aren’t removed, they can damage the cargo by causing uncontrolled ripening, aging, and altering flavor. Therefore, reefers are kept ventilated by fresh air.

- Maintains relative humidity.

Different cargo needs different humidity levels. So, it’s essential to maintain relative humidity according to your goods. A de-humidification setup helps maintain the right levels of humidity in a reefer.

- Drains out excess water from container.

A reefer container has a proper drainage system. In case of water accumulation, the drain in the container will remove the waste.

- temperature can be remotely monitored.

Data loggers monitor supply air temperature, return air temperature, ambient temperature, and humidity level continuously with the help of remote modems.

How much electrical power is required to maintain a reefer container?

The amount of electrical power required to maintain a reefer container at a given temperature depends on the size of the box (TEU or FEU), the temperature of cargo needed, the shipment being carried and the external ambient air temperature.

For example, 9 kW of electrical power is needed to maintain a temperature of minus 18°C in a 40-foot container carrying frozen meat. In comparison, a container carrying fruit at 2°C requires approximately 11 kW. This is because of fruit respire and produces heat during transit. Certain cargoes, for example, bananas, may require even more power because of the more significant heat produced as they ripen. There is a high electrical load on the ship’s generators when reefer containers are carried.

Electrical Power and Plug Requirements for reefer containers.

- All refrigeration machinery must operate from a 380/440 volt, 50/60-cycle electrical power supply.

- The main power plugs shall be 380/440-volt, 32-amp type complying with ISO1496-2: 1988E and CEE-17, 3h IEC309-2 standards.

- It is the container operator’s responsibility to ensure that the temperature-controlled units they use are designed to meet the standard ISO 1496-2.

- When necessary, the container operator shall supply the adapters or pigtails required when the unit’s plugs are not compatible with the ship’s power outlets. These can be kept on board and managed with the spare parts pool.

- When necessary, the container operator shall supply the step-up or step-down transformers required when their container’s power requirement is not compatible with the vessel’s power supply. These transformers can be kept on board and managed with the spare parts pool. All costs associated with the loading, discharging, and shifting of the transformers shall be for the booking Line’s account and arrangement.

Maintenance of reefer container

Refrigeration is a key element in sustaining the quality of fresh produce and extending the shelf-life. Inadequate refrigeration accounts for more than 20% losses of perishable goods. These losses also encompass a huge amount of energy and water loss, with carbon dioxide emissions. Therefore, sustainable cold chain technologies in terms of having more resource-efficient reefer containers improve product quality retention, and reduce induced food losses.

To ensure that all safety regulations are met and that reefers are in prime condition to transport pharmaceuticals, these containers also undergo routine inspections. That’s why it’s important maintain your reefer containers and repair them, whenever required.